Industrial

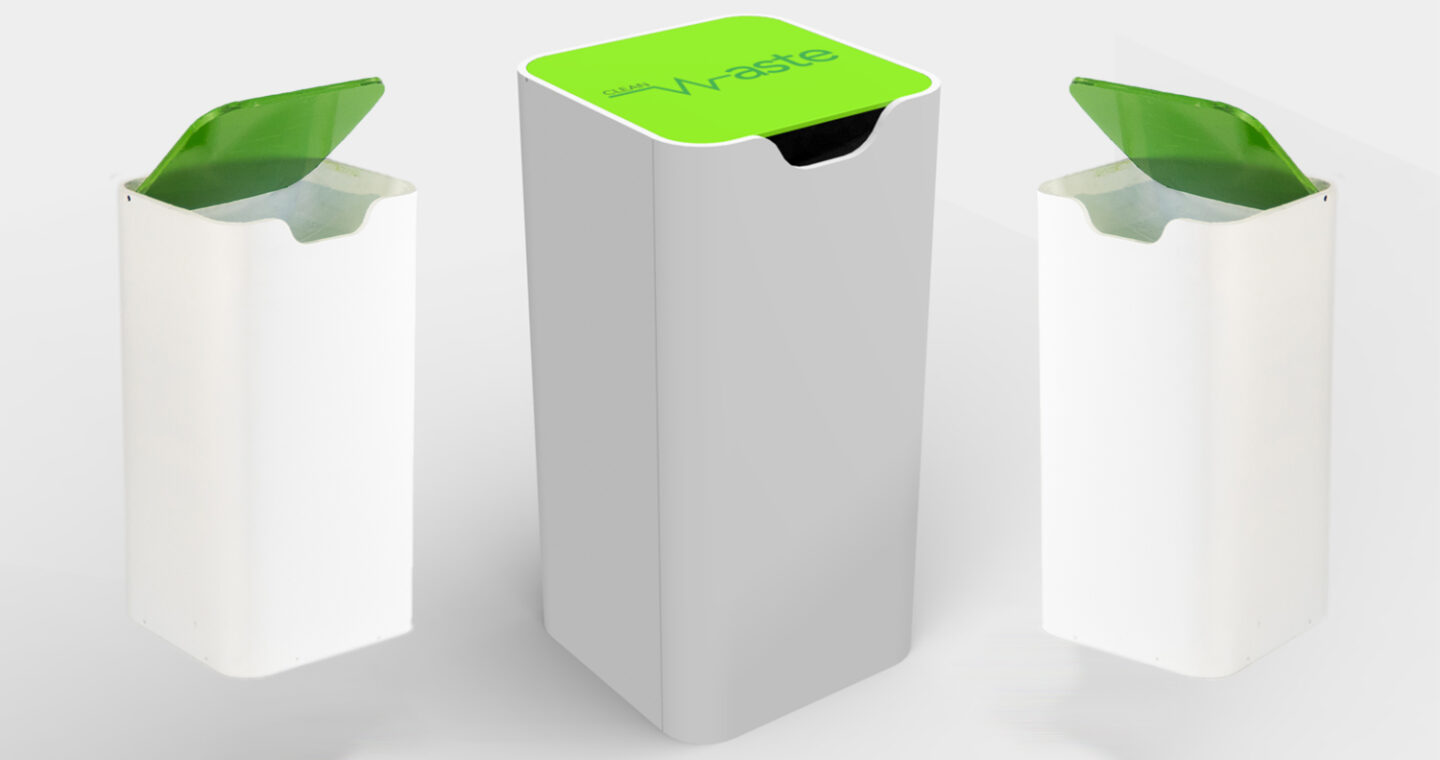

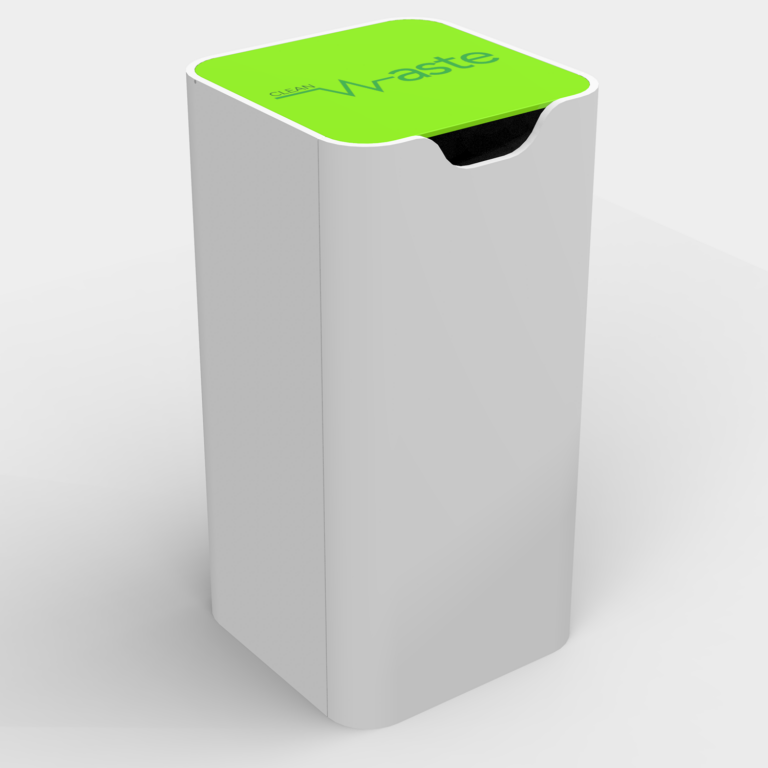

Clean Waste

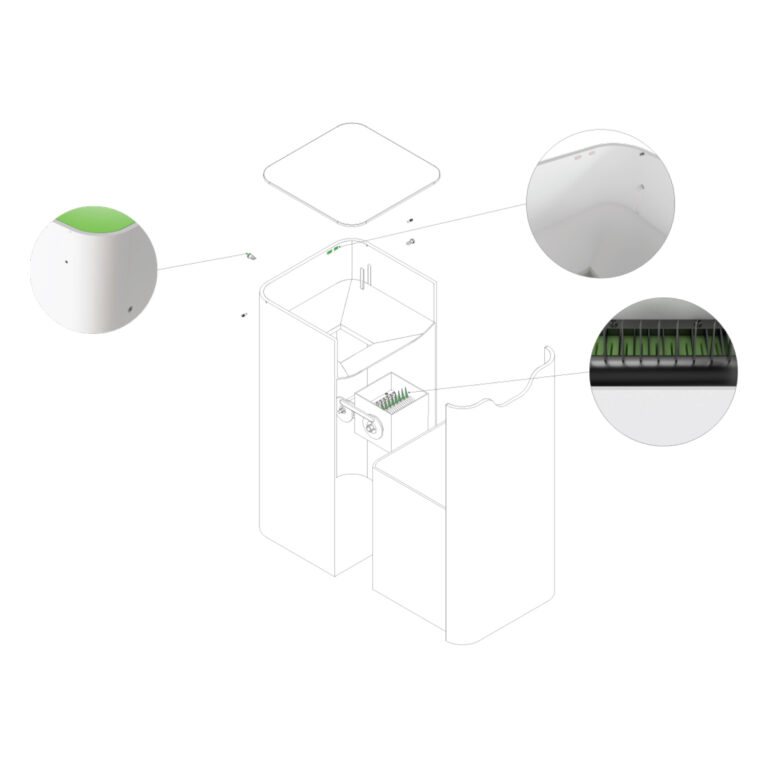

A recycling service which focuses on the niche medical market. Clean Waste is an opt in system where soft plastic packaging is collected and turned into reusable medical equipment and purchased at a lower cost.

Industrial

A recycling service which focuses on the niche medical market. Clean Waste is an opt in system where soft plastic packaging is collected and turned into reusable medical equipment and purchased at a lower cost.

The future of medical packaging and medical equipment is now. Clean Waste is a recycling system which collects, shreds and then remanufactured into medical equipment such as kidney dishes and medicine cups for the hospital.

Clean Waste has been referred to as Green Waste within the documentation and video. It is currently going through a name change.

Luke is a sustainably conscious designer, looking at exploring the future of design based on our failure of the past.