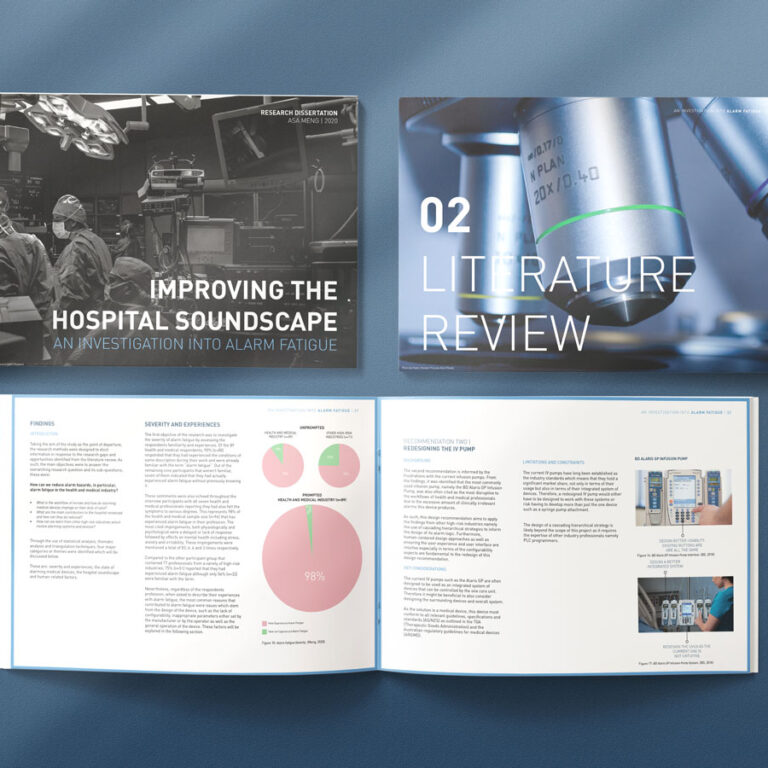

background

Alarm fatigue is a multi-factored and internationally recognized alarm hazard that occurs when an individual is desensitized or overwhelmed by the sheer amount of alarm signals. In the health and medical industry, this has led to health and medical professionals delaying care, missing alarms, turning down the volume, silencing, and in some cases, disabling clinical significant alarms altogether (Graham & Cvach, 2010).

which severely compromises the safety of patients as well as disrupting the workflow of caregivers

but what actually causes all these alarms?

My research aimed to understand a firsthand perspective of the issues surrounding alarm fatigue by investigating:

○ The current state of alarming medical devices

○ Frustrations with the hospital soundscape

○ Other high-risk industries to understand their perspectives on alarm management, design, and workflows

this led to three research questions:

1) What is the workflow of nurses and how do alarming medical devices impinge on their duty of care?

2) What are the main contributors to the hospital noise load and how can they be reduced?

3) How can we learn from other high-risk industries which involve alarming systems and devices?

So what did I find?

MORE IMPORTANTLY, HOWEVER, IS THAT THE MAJORITY OF ALARM SIGNALS FROM MEDICAL DEVICES WERE DUE TO FUNDAMENTAL DESIGN ISSUES SUCH AS:

discoverability, menu navigation, workflows & ergonomics

which causes

Human Input Errors

SO WHAT CAN I DO to address these issues?

brief

To design a product, system, or service for health and medical providers in the hospital environment that minimizes human input error thereby reducing alarm fatigue and improving the hospital soundscape with a potential to support or aid patient recovery.

objectives

• Improve the hospital soundscape by minimizing the risk of human input error and alarm fatigue

• Aid patient recovery where applicable

• Allow the operator to configure all parameters for individualized patient and care provider needs

But how?

By redesigning the Intravenous (IV) Pump

Identified in my research as being the most disruptive noise contributor in the hospital environment.

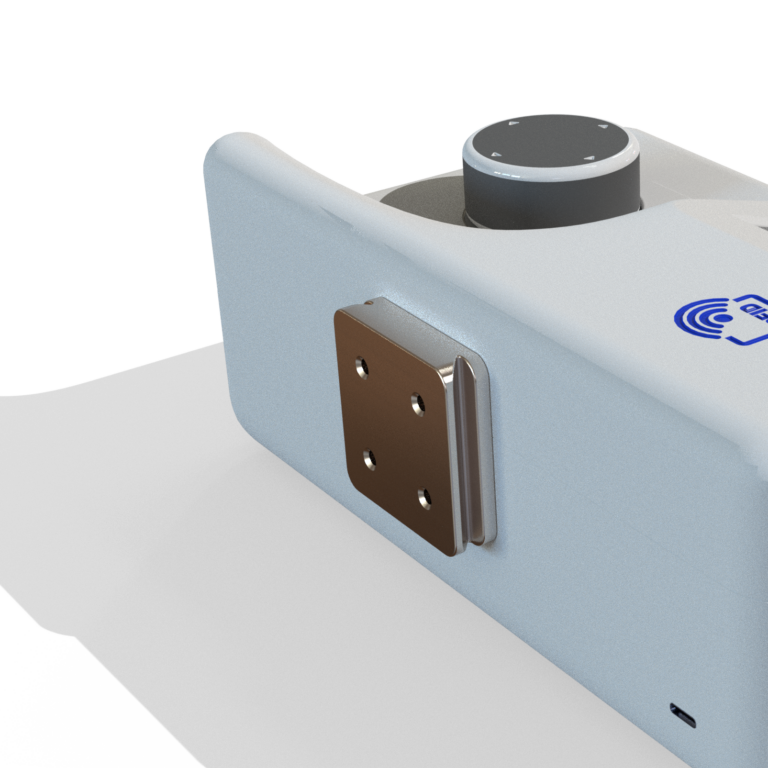

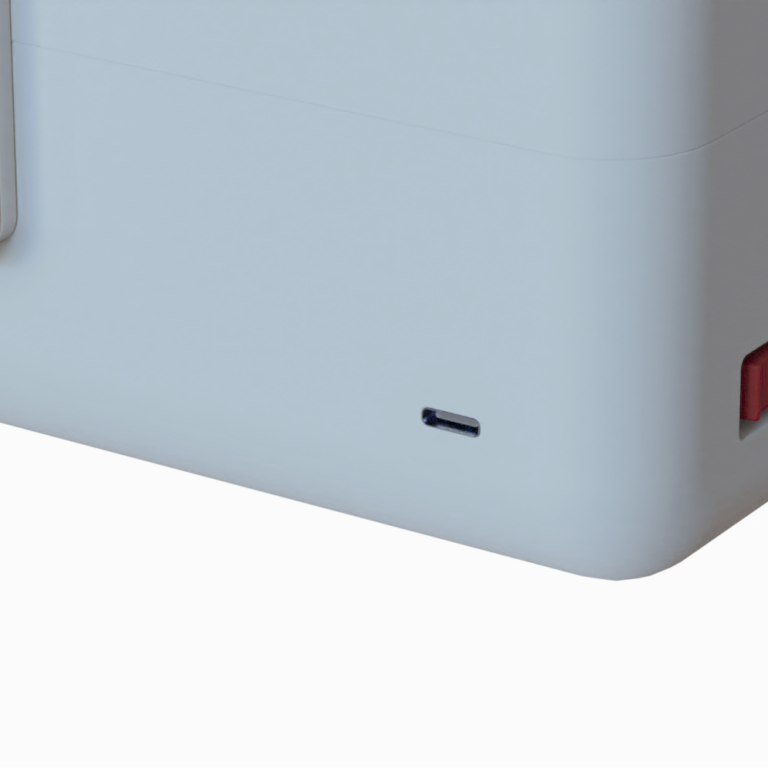

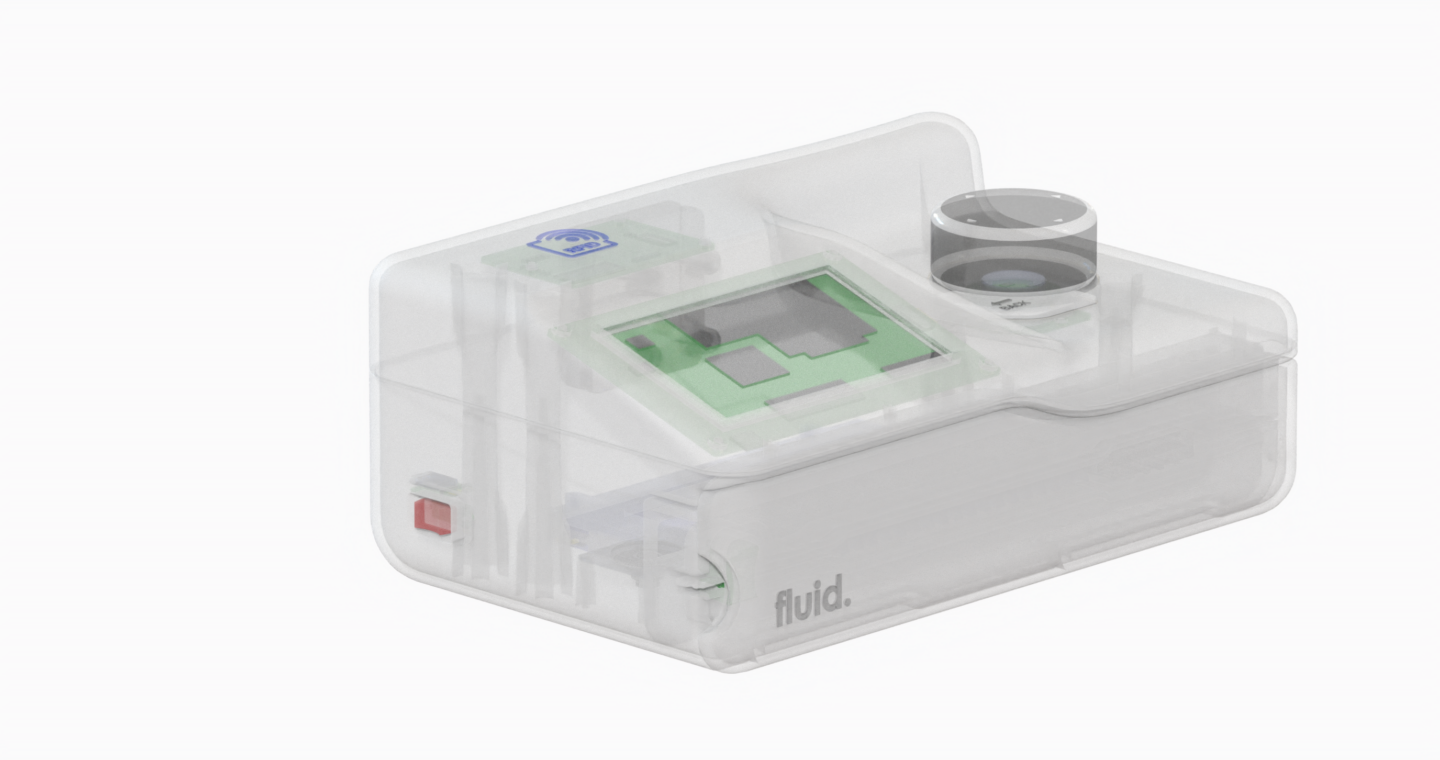

Introducing: Fluid

a large volume infusion pump that rethinks the workflow of infusion therapies

SEQUENCE OF USE

So how does Fluid address the issues of Human Input Errors & Alarm Fatigue?

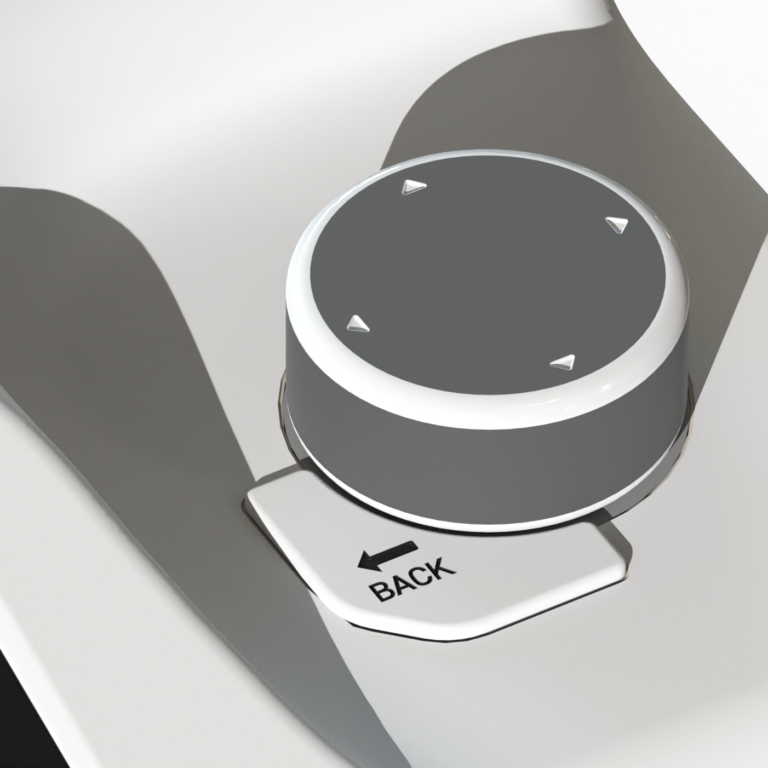

PRODUCT FEATURES

3D MODEL

PRESENTATION MODEL

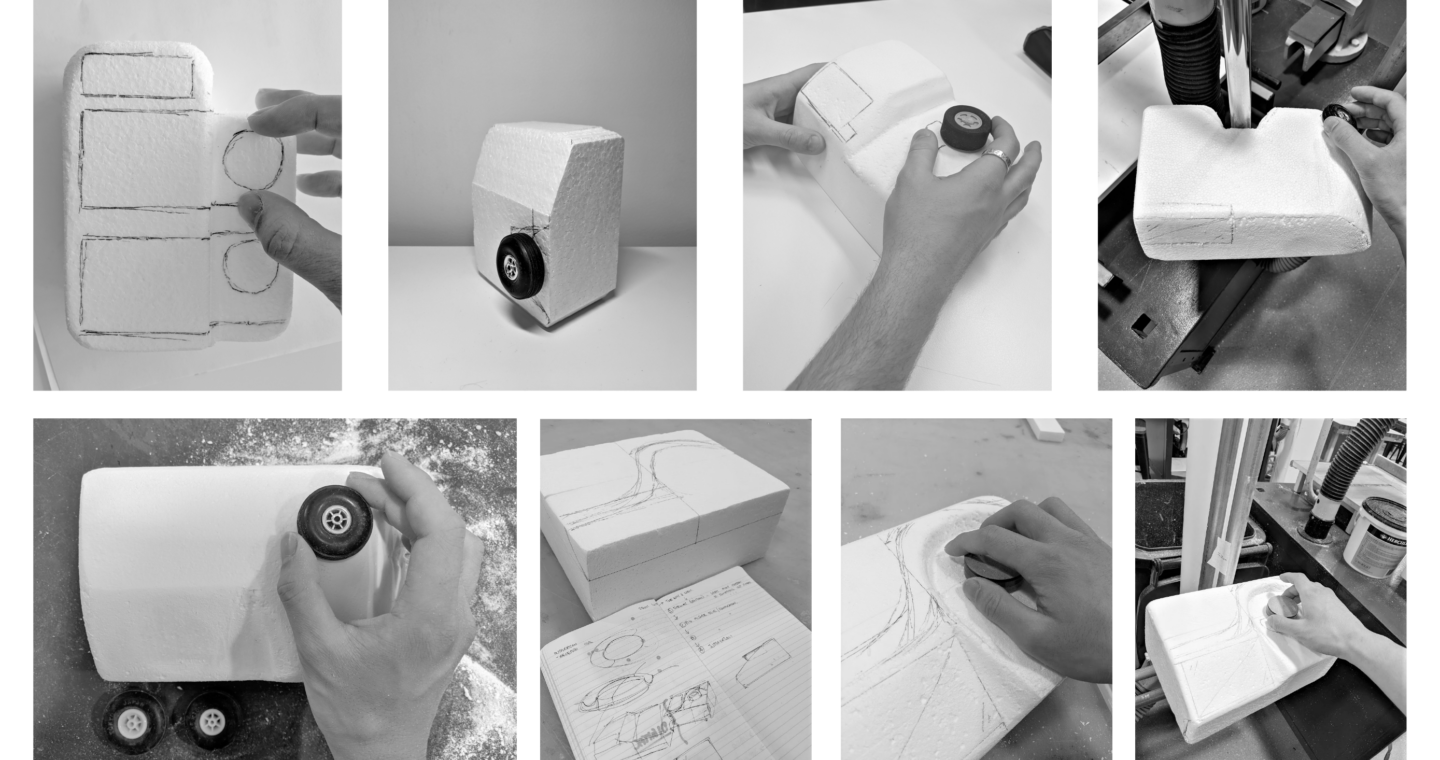

Model Making Process

Product Details

Click the arrows below to see more

Model Making Process

Want to find out more about Fluid?

Technical Drawings and Documentation

Asa Meng – Fluid | Dissertation

Thank you for viewing my project! let’s keep in touch 😃

-

Website

-

Email

-

LinkedIn

https://www.linkedin.com/in/asameng/