Industrial

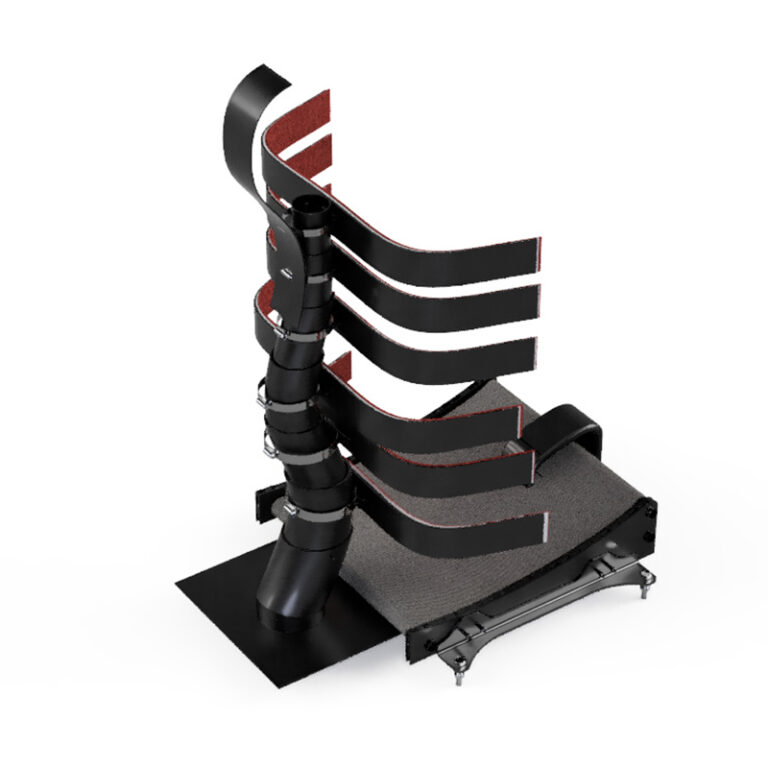

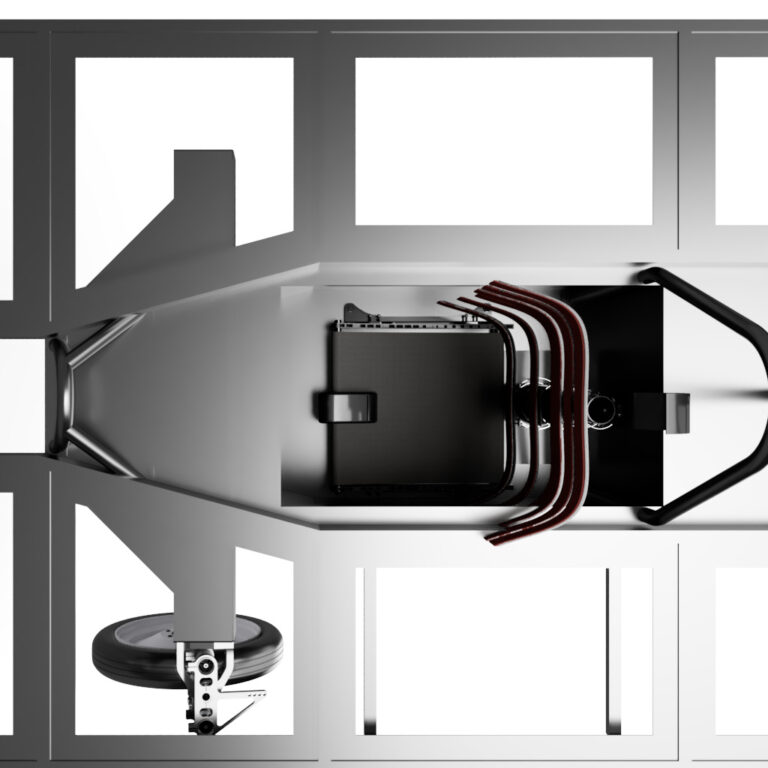

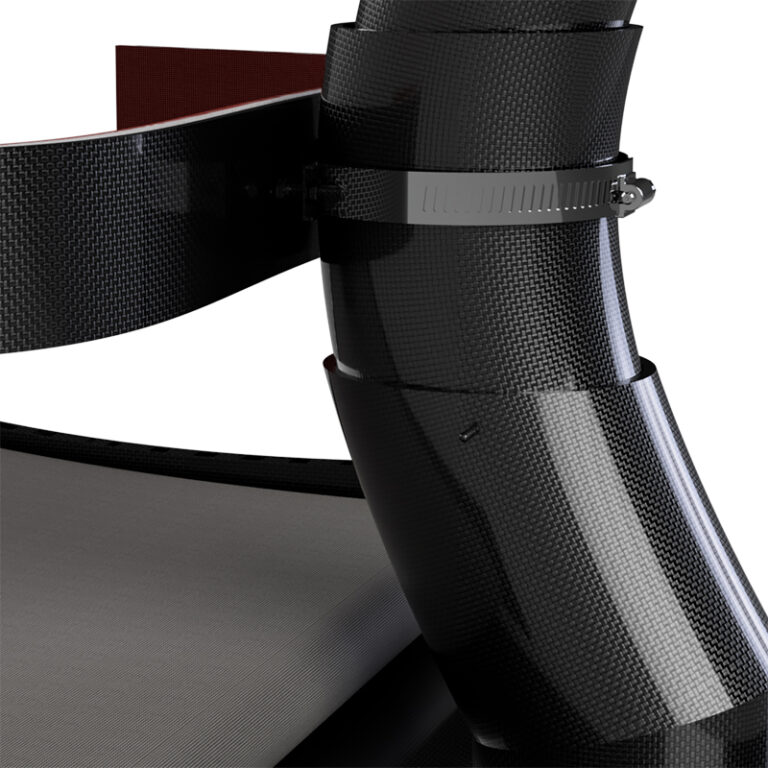

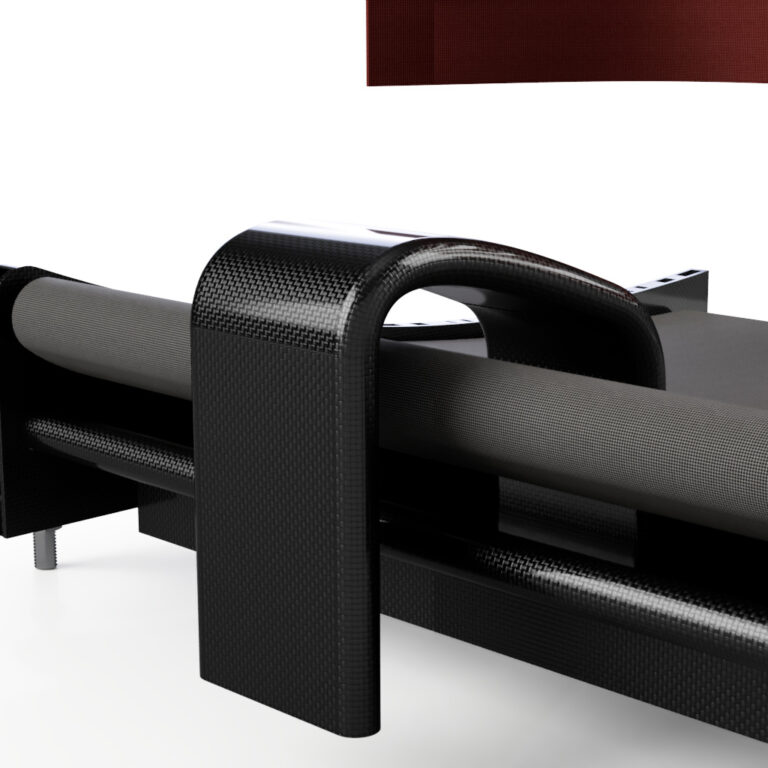

Solar Vehicle Seat Design

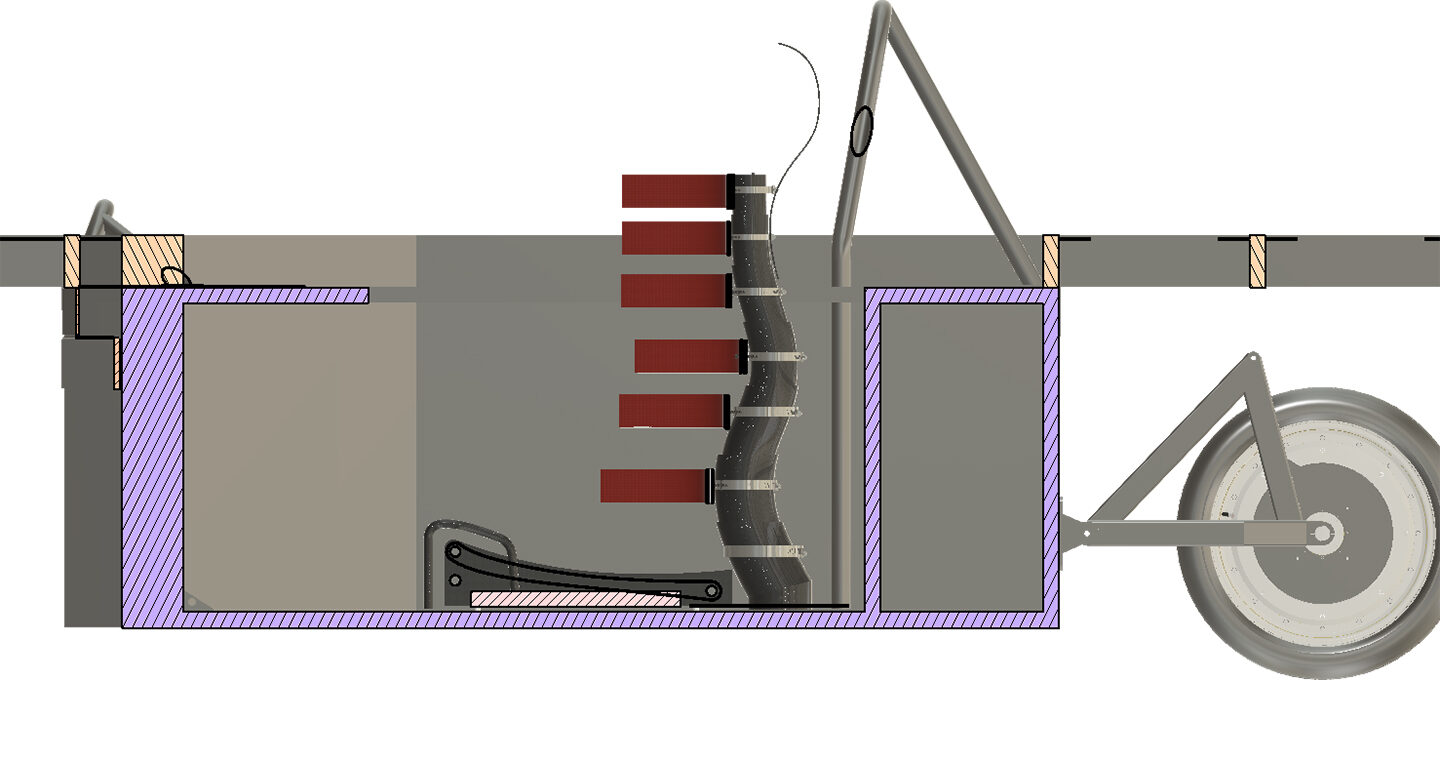

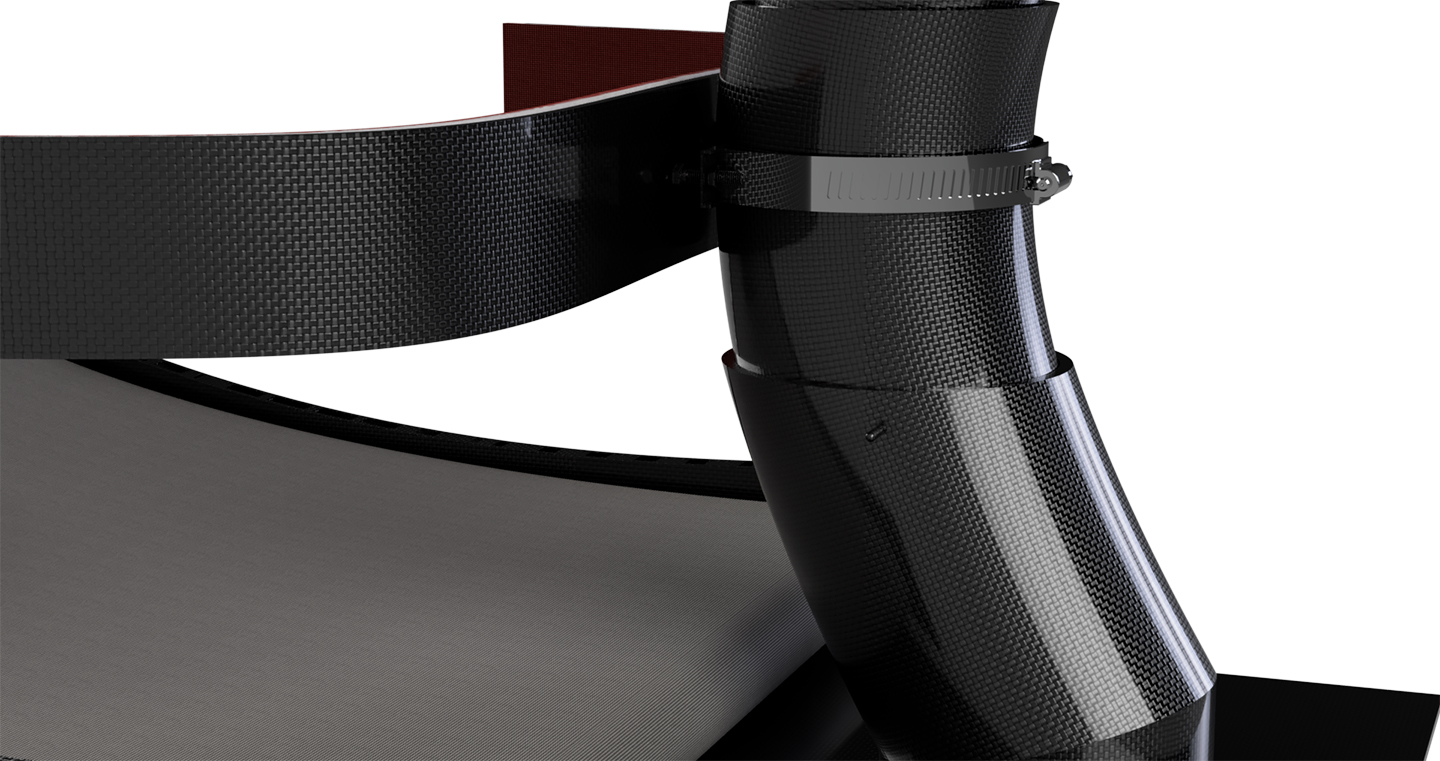

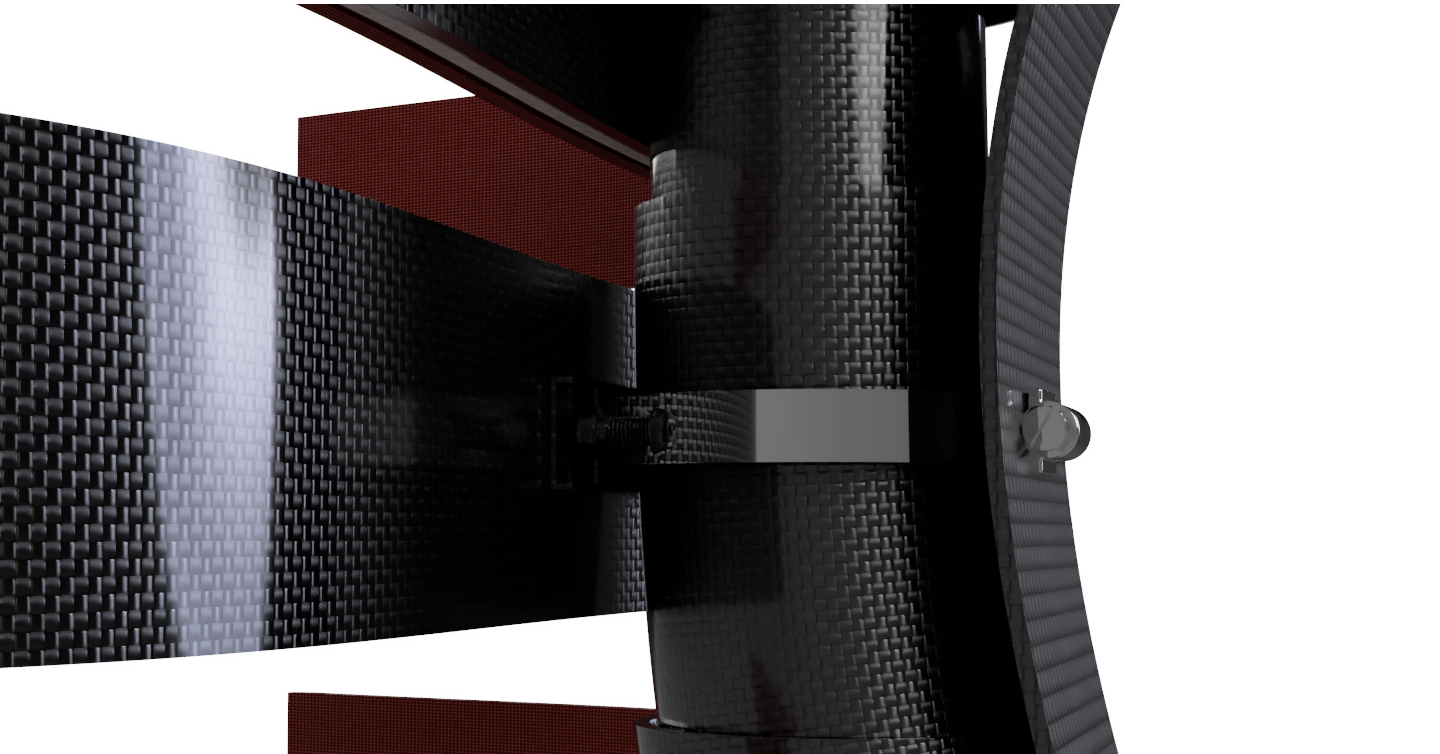

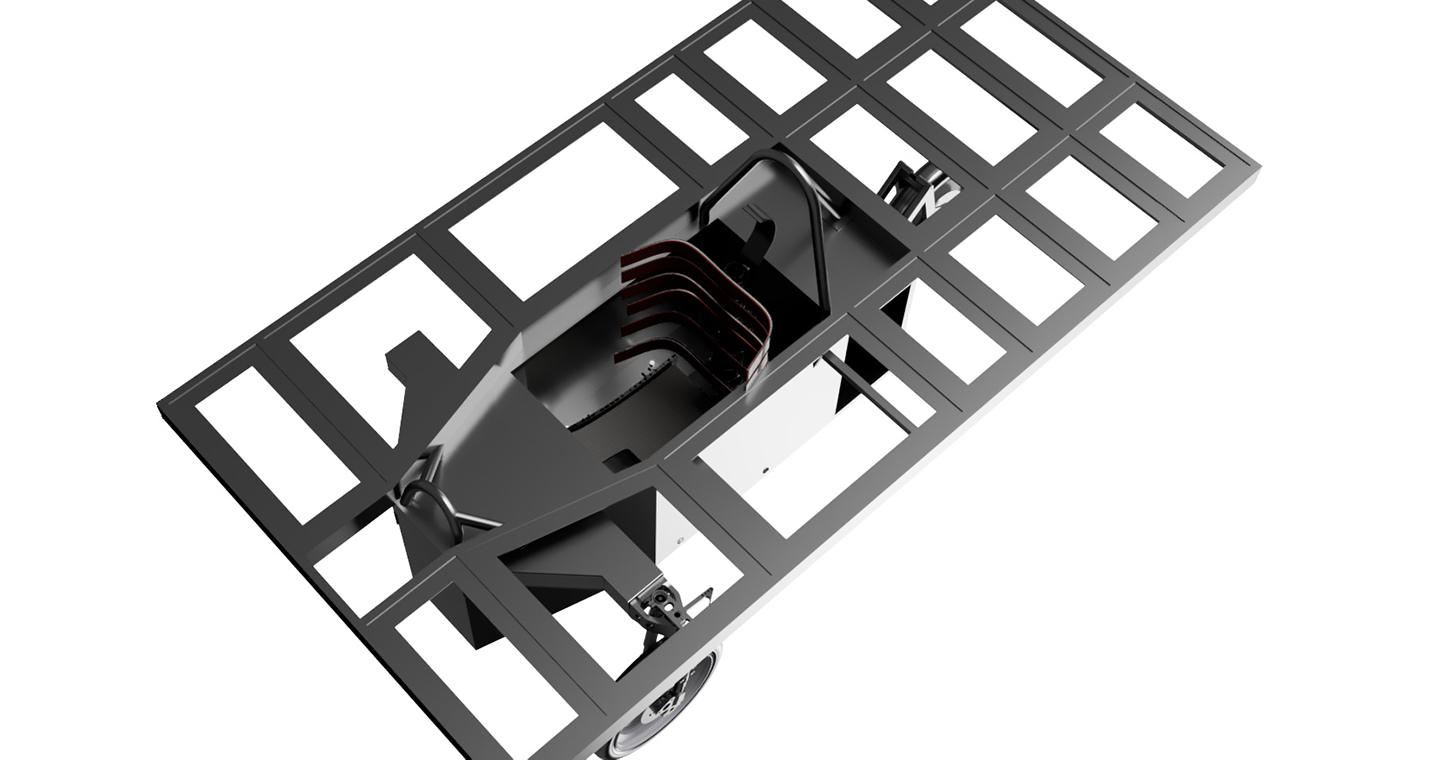

This project was done in partnership with Team Arrow Racing Association. The seat design is tailored to the needs of drivers within Team Arrow and not to solar racing in general. The final seat design adheres to regulations mandated by Bridgestone, the organisers of the Bridgestone World Solar Challenge a race that inspires innovation in the fields of solar technology, electric vehicles, and vehicle design.